Compass RT

Tagline

About CompassRT:

CompassRT is an innovative software solution tailored specifically for knitting factories to streamline fabric roll tracking processes. Our platform leverages state-of-the-art technology, including integration with automatic weight scales, to ensure seamless, accurate, and efficient production operations.

Why Choose CompassRT?

- Reliability: Proven technology that ensures seamless operations.

- Accuracy: Advanced tracking systems for error-free results.

- Efficiency: Reduced production time and enhanced productivity.

- Sustainability: Minimizing waste and optimizing resource utilization.

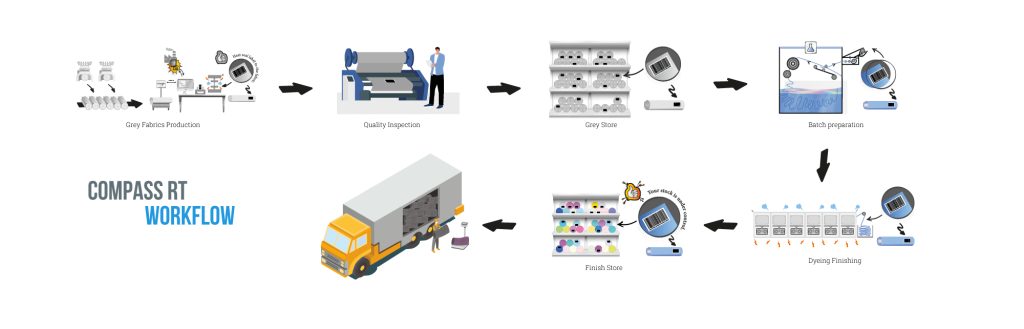

Compass RT Work Flow

Key Features

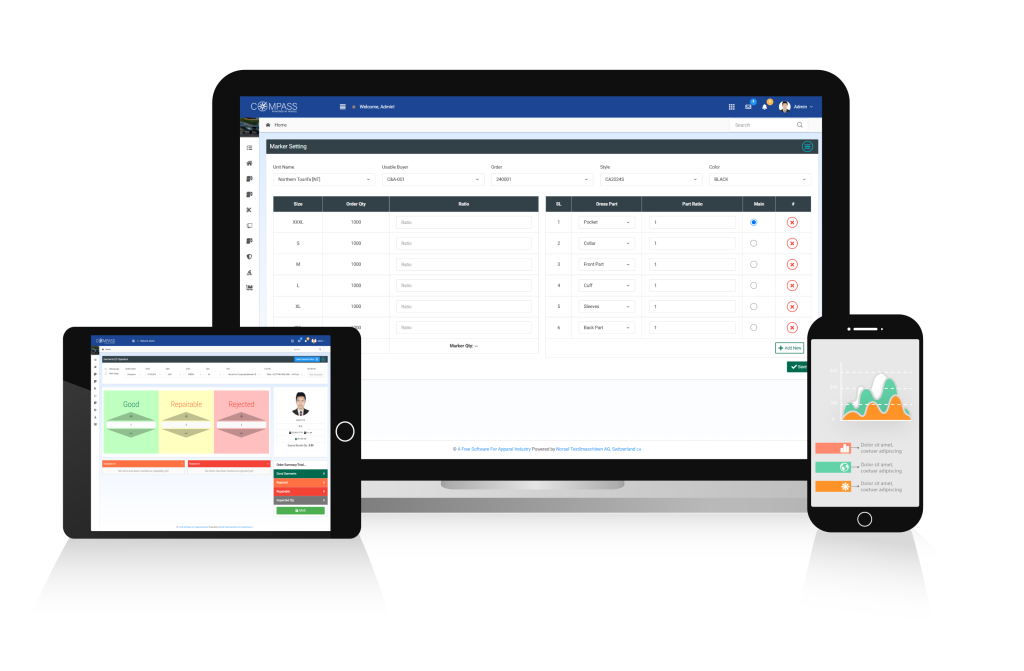

Automated Roll Tracking:

- Every fabric roll is tracked automatically using advanced weight scales.

- Eliminates manual errors, ensuring precise record-keeping.

Optimal Accuracy:

- Achieves unmatched accuracy in tracking and production data management.

- Reduces inconsistencies and ensures reliability.

Efficiency in Production:

- Enhances production workflows by minimizing delays and inefficiencies.

- Promotes streamlined operations.

Loss and Waste Reduction:

- Mitigates fabric wastage and process loss.

- Ensures maximum utilization of resources.

Roll Missing Prevention:

- Prevents roll misplacement or loss through continuous tracking.

Manpower Optimization:

- Reduces reliance on manual labor.

- Allows staff to focus on higher-value tasks.

Real-Time Reporting:

- Generates automated production reports in real time.

- Facilitates data-driven decision-making for better productivity.

BENEFITS OF Compass RT

Operational Process Optimization

Operational Process Optimization

- No hand written documents

- System generated label

- System generated delivery slip

- Scan only operation ensures low or zero training

Increase Efficiency:

- Improve traceability

- Zero human error

- No additional data entry operator requires

- Establish efficient human involvement

- Ensure re-using slow moving fabric

Data Driven System

Data Driven System

- Automated production entry

- Job/Program wise fabric production status

- All information can be downloaded in .xls to analyze or to import to any other system

- Automated movement tracking

- Live stock management system

- Green signal for live

Real-Time Visibility:

- Best utilization of slow moving fabric

- WIP (Work In progress) information - anytime, anywhere

- Real time data driven decision making

- Lead time management/optimization

- Decision about slow moving and blockage stock

Production Data

Daily Production: 10,000 kg

Yearly Production: 3,000,000 kg

Stock Overview

Slow-Moving Stock (Yearly): 30,000 kg

Blockage Stock (Yearly): 15,000 kg

Wastage Calculation

Wastage Fabric: 15,000 kg

Cost per kg: $4

Wastage Cost: 15,000kg×4$/kg=60,000$

Total Wastage Cost: $60,000

Production

Production:

- Automated production information

- Automated weight entry right from weight scale

- Operator information just by scanning barcode or RFID of the operator

- Optimal Accuracy

- Notify about additional production

Reliability:

- Accuracy in all steps - through iot/device based data entry

- Scan based operation - no error

- Scan based operation - nearly zero training

- No additional human involvements - same machine operator does the task

- It reduces humans that was required for production information entry during manual operation

Time for Labeling

Manual Roll Marking Time: 7 minutes per roll

Auto Labeling Time: 2 minutes per roll

Time Saved per Label: 7min−2min=5min

Cost Savings Per Day: 26.67$

Total Time Saved

Total Saved Time: 2,000 minutes

Machines in Operation: 40

Time Saved per Machine: 50min per machine

Yearly Cost Savings: 8,533$

Machine

Machine:

- Top Idle machines

- Machine usages report

- Top 10 machines that creates most quality issues

- Machine wise quality report

- 4 point information system

Data Driven Decision Making:

- How to increase usages of machines that lead to more production

- Finding the reason and resolve issues relatively quicker

- Helps to identify which machine generates most quality issues

Shift:

Shift:

- Shift wise production report

- Shift wise production efficiency

- Shift wise Quality Report

Shift Efficiency:

- Management can focus and take initiative to improve low performing shift

- Measure shift efficiency by comparing shift wise data

- Helps to identify which Shift generates most quality issue

Quality Monitoring

Quality Monitoring

- Quality Grade Monitoring Instantly

- Identify reasons of quality issues through -

A) Shift wise quality Report

B) Machine wise quality report

Enhanced Quality Control:

- Analyzing the data quality of production can be improved

- Reason for quality issues can be figured out

- Upfront quality information helps to keep production on track

Accountability

Accountability:

- Ensure accountability of an operator

- Visibility on operator performance

Operational Transparency:

- Operator wise production tracking

- As operator information is tracked so improved visibility ensures betterment in performance automatically

Add Your Heading Text Here

Add Your Heading Text Here

Add Your Heading Text Here

Add Your Heading Text Here

Add Your Heading Text Here

Add Your Heading Text Here

CONTACT US

Request a Free Demo

- Real- time Production visibility

- Operation Process Optimization

- Increase Efficiency

- Data Driven System

- Reliability

- Data Driven Decision Making

- Enhanced Quality Contorl

Please Inter Your Information

GET A FREE CONSULTATION

987 233 0000

Vero id posuere tempus aspernatur quaerat mollis voluptatum eveniet porro viverra libero habitasse Aut ab nibh aliqua optio veniet porro viverr.